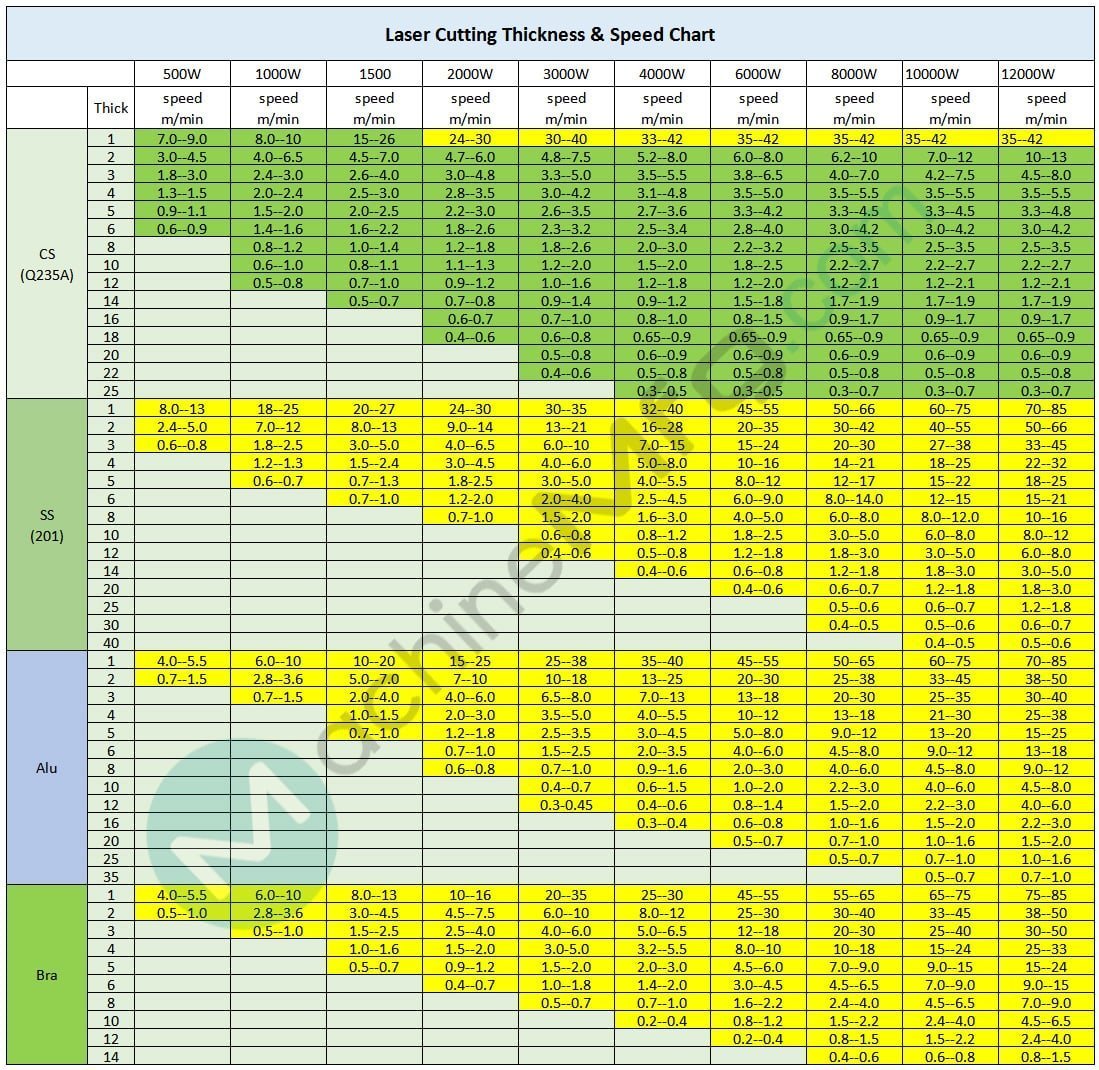

The maximum cutting rate production rate is limited by a number of factors including laser power material thickness process type reactive or inert and material properties.

Laser cutting wood maximum thickness.

Fedtech s custom manufacturing services include both laser cutting services and waterjet cutting services with value engineering capability complete cad cam capability same day quotations and competitive pricing.

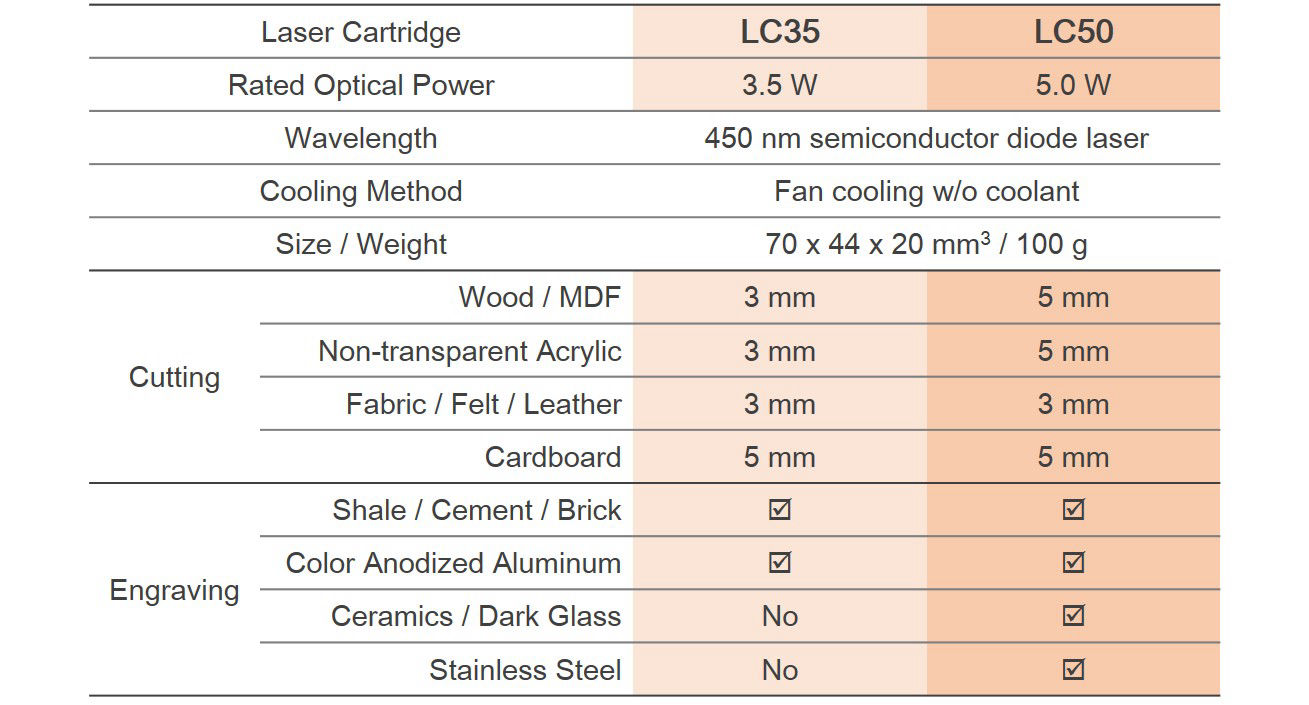

We have compiled this guide for the laser system that we sell which gives you a good idea of all kinds of materials that a laser can mark engrave drill and cut from the commercially available options that we provide.

It tends to be either 1 4 ish or 1 2 ish the latter being too thick.

Wood is great for many projects but hand cutting is difficult and time consuming.

For many purposes a laser can be up to thirty times faster than.

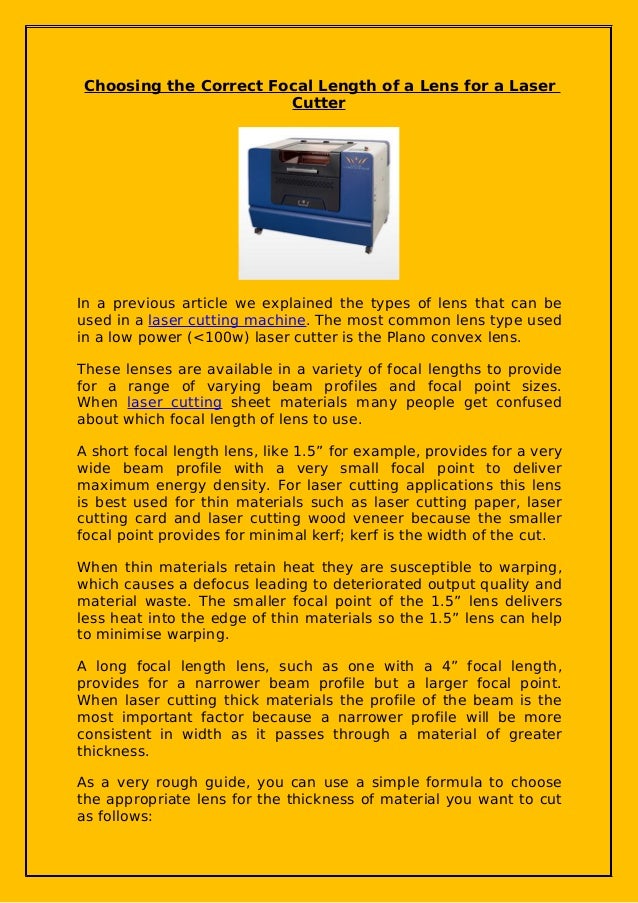

Laser cutting involves cutting the material with a powerful and precise laser which focuses on a small area of material and can cut a thickness of up to 15 mm.

The following data in the laser cutting thickness speed chart is for reference only.

The maximum sheet thickness our lasers can cut is around 9 10mm however it is tough to find plywood that actually comes in this thickness in the usa.

Here is a benchmark guide to how thick of a material we can cut.

The other challenge we face with plywood is getting thinner sheets which are high enough quality for laser cut products.

Common industrial systems 1 kw will cut carbon steel metal from 0 51 13 mm in thickness.

Laser cutting bed size.

The difference between waterjet cutting and laser cutting lies primarily in thickness cutting ability material choice and accuracy required for different.

Listed are the maximum thicknesses for each material that we can cut.

The size of our laser cutting bed is 18 x 32 which is the maximum sheet size we can cut.